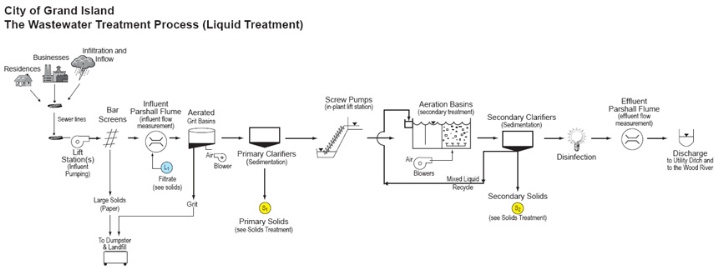

Click here to View a PDF of this image.

Liquids Processes Treatment Steps

Below are descriptions of the liquid treatment process listed in sequence, and following the flow of the schematic. The liquid and solid treatments processes are inter-related. Solids are derived from and separated from the liquids treatment process.

1. Sewer Collection System

Sewage is collected through a network of pipes and manholes from residences, businesses, and from industries. Most sewage flows by gravity through the pipes. Manholes are used to allow access for cleaning. A significant amount of the sewage is from stormwater (rainwater) or from groundwater that seeps into the sewage collection system.

2. Lift Station(s) (Influent Pumping)

Lift stations provide pumping to lift sewage from the deep sewer a higher level where it can flow, via gravity, into the treatment plant. There is a large lift station, also known as the headworks, at the start of the wastewater plant process.

3. Bar Screens

Bar Screens remove solids from the influent which are larger than one inch (like sticks, plastic gloves, tampons, and other items). Solids are raked off the screen and put into a dumpster. The dumpster is hauled to the landfill.

4. Grit Basins

Heavy solids drop to the bottom of the basins and are directed toward a low spot using an auger. From the low spot a pump is used to suck out the solids and pump it through a hydro-cyclone and grit classifier to spin out the solids and deposit them into a dumpster. Solids removed include sand, corn, metal shavings, and other items. The solids removed from this process are taken to the landfill.

5. Primary Clarifiers (Sedimentation)

Clarifiers are settling tanks where solids are settled out and collected. These “primary” clarifiers remove solids such as soil, coffee grounds, or other waste matter. Flow enters the center of the clarifier then moves out toward a weir. As it travels outward, the flow moves progressively slower and more solids are deposited as it passes through the process. Additionally, scum (floatable solids) is collected at the top of the primary clarifiers. The scum is pumped to the secondary sludge holding tanks, also referred to as Waste Activated Sludge (WAS) tanks. Solids removed from the primary clarifier, called primary solids, are pumped and discharged to holding tanks for dewatering.

6. Screw Pumps (In-Plant Lift Station)

Screw pumps provide additional lift for the sewage to move it to the secondary treatment process. Screw pumps (Archimedes screws, which look like an auger) are used because of the large flow and low lift required.

7. Aeration Basins (Secondary Treatment)

Flow from the screw pumps is aerated and mixed in these long rectangular basins. These basins are designed to allow commonly available micro-organisms (bacteria) to come into contact with the sewage and to eat their way to clean the sewage. The bacteria is the real “treatment” process. Carbon source, ammonia, and many other items are removed in this way. Aeration basins are used to maximize the growth of the bacteria. Flow is mixed to keep sludge from settling. At the beginning of the basin, additional micro-organisms are added to the process stream to allow the bacteria a “head-start” in their growth. These bacteria are simply recycled from the end of the basin back into the beginning. This allows increased treatment efficiency.

8. Secondary Clarifiers (Sedimentation)

Flow from the aeration basins is settled in the secondary clarifiers. Clarifiers provide a settling area where the solids are settled out and collected. The solids from the secondary clarifiers consist mostly of bacteria which has eaten the waste from the sewage. A portion of the solids (bacteria) are recycled to the aeration basin to provide additional bacteria growth. The remainder of these secondary solids is pumped into an aerated holding tank before dewatering.

9. Disinfection

During the outdoor recreation seasons (May-October), any remaining micro-organisms in the water are treated using ultra-violet light. The flow passes near a specially-designed light-bulb and the bacteria are sterilized rendering them inert and unable to reproduce. This is the final treatment step. Flow is measured as it exits the treatment plant using a Parshall flume.

10. Effluent Parshall Flume (Effluent Flow Measurement)

This structure measures the effluent flow to direct equal amounts of flow treated by the WWTP. Many plants use this flume because of its accuracy and ease of operation.

11. Discharge

The treated flow, now in compliance with regulatory requirements, flows by gravity to a utility ditch adjacent to the WWTP and then on to the Wood River.