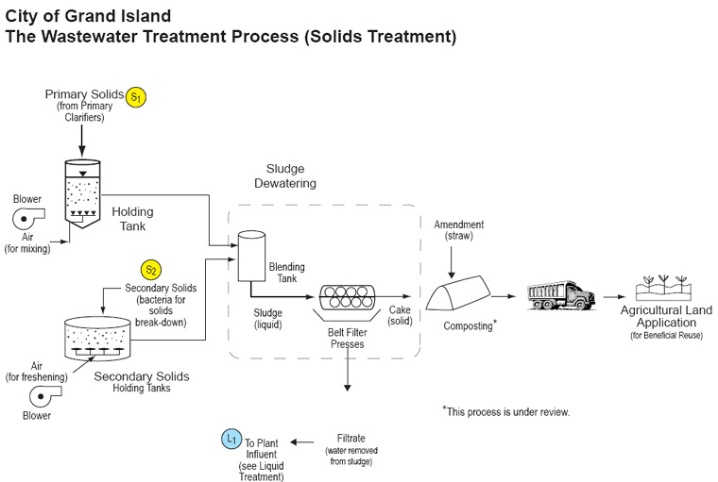

Click here to View a PDF [PDF] of this image.

Solids Processes Treatment Steps

Below are descriptions of the solid treatment processes listed in sequence and following the flow of the schematic. The solid and liquid treatment processes are inter-related. Solids are derived from and separated from the liquid treatment process.

1. Primary Solids (Sludge)

This sludge, taken from the primary clarifiers, is pumped to a holding tank where it is aerated and ferric chloride is added for odor control. Air mixes the sludge and keeps it from becoming solid. Solids are thick at this stage, similar to a wet cement. Special equipment is needed to pump these solids.

2. Secondary Solids (Sludge)

This sludge is collected from the bottom of the secondary clarifiers and is pumped to a holding tank. The tank is aerated to keep the sludge mixed. Secondary solids are mostly water which can be pumped and will flow like water. Scum (floatable solids) from the primary clarifiers are also scraped off and stored in these holding tanks.

3. Sludge Dewatering Process

The dewatering process is used to remove water from the primary solids and secondary solids and turn these solids into a thicker cake-like substance. Primary sludge and secondary sludge are mixed in a blending tank then processed through a belt filter press. The press places two porous sheets around the sludge. The sheets and sludge are then pressed together through a series of rollers. Water (filtrate) is squeezed out from the sludge and a cake remains. The water, still slightly dirty, drains separately back to the head of the wastewater treatment process. The cake is loaded onto a truck for disposal at the landfill.